For over 50 years, Ansys software has empowered innovators to break new ground with predictive simulation technology. From sustainable transportation and cutting-edge semiconductors to satellite systems and life-saving medical devices, Ansys drives the next major advancements in human progress.

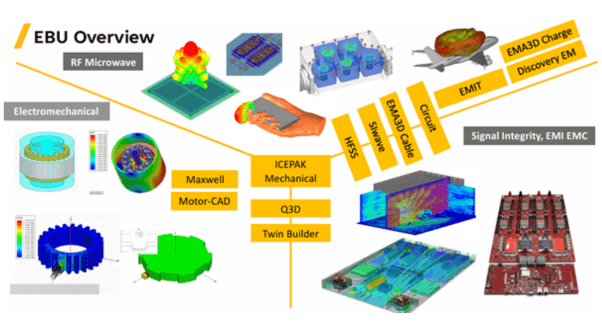

Ansys Electronics products are EM simulation tools for low and high-frequency electronic products that cater to different industrial sectors like automotive, aerospace, healthcare, consumer electronics and large electrical machines environments, IoT. The Electronics product line is the engineer’s all in-one-solution to study numerous electrical phenomena and dynamically unify it with thermal and mechanical effects.

Signal Integrity (SI) Analysis, Electromagnetic Interference (EMI) and Compatibility (EMC), Electromagnetic simulation, Thermal Management, Power integrity and reliability, Mechanical Stress Analysis

Featured Products

ANSYS SIwave, ANSYS HFSS, ANSYS Icepak, ANSYS Mechanical

Design and electromagnetic analysis of Electrical & Electronics systems, Thermal management of electronic devices, Structural Analysis, Efficiency Optimization, Vibration and Noise Prediction, Electrostatic Analysis, System level analysis, Magnetic Latching

Featured Products

Ansys MotorCAD, Ansys Maxwell, Ansys Icepack, Ansys Mechanical, Ansys Fluent, OptiSlang, Simplorer, Ansys Twin Builder

Component design, Antenna placement and integration, Antenna array, Co-site interference, Lightning strike, Rotor blade modulation, large scale platform interaction, RCS (Radar Cross Section) Analysis, Electromagnetic Compatibility (EMC) and Interference (EMI).

Featured Products

ANSYS HFSS, ANSYS Icepak, ANSYS EMA3D Cable and chart, ANSYS STK

Pack and module management, Reliability and fatigue prediction, Battery Management Systems Design and Validation, System-Level Simulation, System Architecture Selection, Functional Safety Analyses and Cybersecurity, Embedded Software Development and Validation.

Featured Products

Ansys Twin Builder, Ansys Medini Analyze, Ansys SCADE, Ansys Icepack, Ansys Mechanical, Ansys Fluent, Ansys Sherlock

MECF is one of the largest CFCs (Common Facility Centers) approved by MeitY (Ministry of Electronics and Information Technology) under the EMC (Electronic Manufacturing Cluster) scheme is located in Pune( Maharashtra). We have recently partnered with MECF offer the latest technologies and equipment for testing and certification, with a pay-for-use model.We deliver powerful simulation services for electromagnetic, thermal, and mechanical analysis, ensuring optimal performance in designs like PCBs, power electronics, and 5G systems. 3D Engineering services can helps companies bring innovative, reliable products to market faster, driving advancements in automotive, telecom, and IoT industries.

3D Engineering has successfully implemented specific case studies within the pharmaceutical and process industries, showcasing significant benefits to our customers in terms of cost and time savings. Our solutions have streamlined manufacturing processes, optimized product development cycles, and connected numerous industry experts to drive innovation and efficiency.

3D engineering was incepted in 1999 with the aim of becoming the market leader in providing PLM Solutions to the manufacturing industry. Till date, we have served more than 1000 enterprises across diverse geographies and has become the leading channel partner for Siemens Industry Software, Distributor for ANSYS, Distributor for 3D Systems Additive Manufacturing solutions and CAE & Manufacturing Simulation Services provider in India. With our headquarter in Pune, 3D Engineering has a presence through field engineers in West India (Pune, Mumbai, Gujarat, Aurangabad) and South India (Bangalore, Chennai, Hyderabad).

Read More …

3D Engineering is a prominent engineering product solution provider that has expertise in CAD/CAM/CAE/PLM/Digital Manufacturing solutions. We have numerous certified trainers on our board with many years of valuable industry experience. Our association with prominent brands like Siemens Industry Software, ANSYS, 3D Systems, Intech Additive establishes 3D Engineering as the right technology partner for all industry verticals. We offer effective customer support services and are committed to deliver more value to our customers’ businesses by providing better returns on their investments.

3D Engineering technology basket includes a) Siemens Industry Software: NX CAD, Solid Edge, CAM, Teamcenter and Tecnomatix. b) Ansys Solutions: Structural Mechanical, Multiphysics Simulation, Fluid and Electromagnetic (LF & HF) Simulation c) 3D Printing/Additive Manufacturing Machines for industrial Plastics and Metal Printing d) Engineering services – Product Design, CAE Simulation, Process Simulation and Digital Manufacturing.

Read Less …

In the business of providing engineering products

Customers across India

Support team with hands-on industrial exposure

Engineering product company

Competent Engineers

Focused partnership approach