Overview

With ever shrinking timelines and budgets, CAE simulation is an important tool in the hands of designers and engineers. Modern CAE simulation tools help engineers run various what-if scenarios before a product is made. Our expert team of simulation engineers; can help you put together a simulation model which can accurately represent various phenomena experienced by the product. We have experience of putting together parametric simulation models with specific design goal. We work hand in hand with our customer teams to ensure that our simulation models meet strict deadline, meet quality criteria and reduce the overall development costs.

Fields / Applications

Our team of expert engineers has experience in using structural mechanic simulations across automotive, aerospace, process, and energy industries.

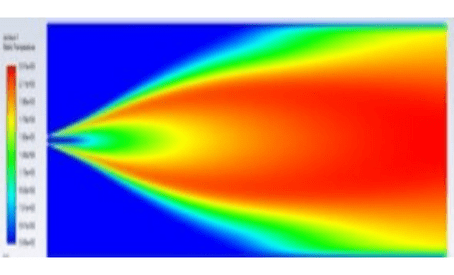

CFD –Computational Fluid Dynamics

We have access to modern CFD modeling software along with state of the art high performance computing infrastructure. With the help of this, we can help our customers solve complex steady state problems along with long duration transient simulations.

Incompressible and Compressible

Key Features

- Compressible gaseous flow

- Incompressible liquid flow

- Phase change

Steady State and Transient

Key Features

- Time independent flow – Steady state

- Flow varying with time – Transient

- Steady state flow simulation – Computationally economical

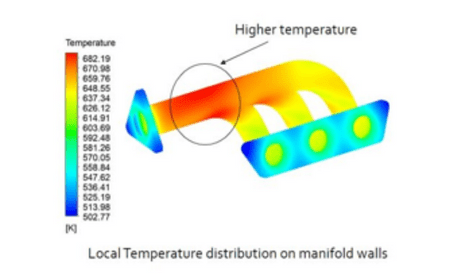

Conjugate Heat Transfer Analysis

Key Features

- Combination of convection, conduction and radiation modes

- Powertrain cooling

- Exhaust system cooling

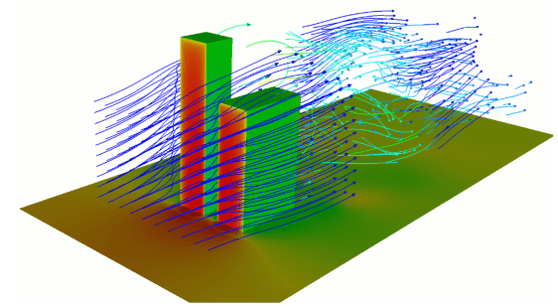

Wind Load Calculations

Key Features

- Communication and power transmission towers

- Solar power fields

- Automotive drag calculations

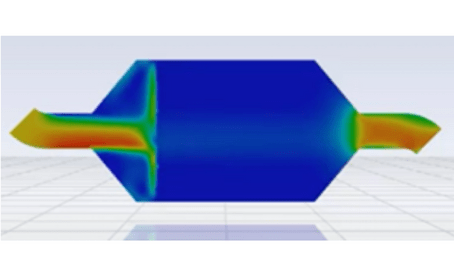

Porous Media Analysis

Key Features

- Exhaust systems

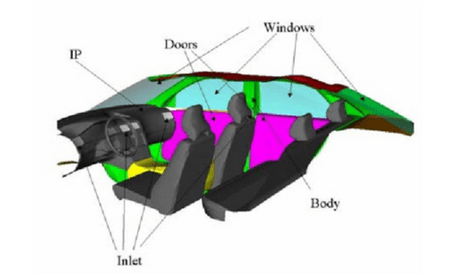

- HVAC

- Filters

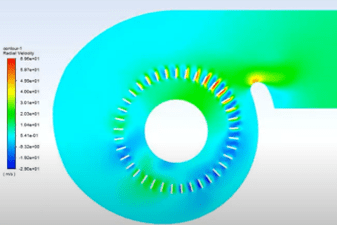

Moving Reference Frame – MRF

Key Features

- Turbomachinery

- Pumps

- Pharma and chemical mixers

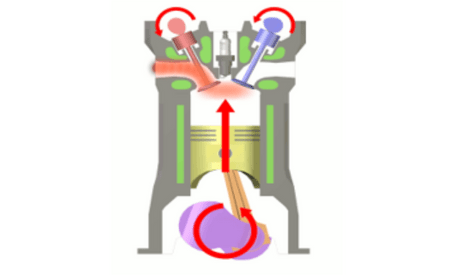

Moving Mesh Simulation

Key Features

- Adaptive mesh creation

- IC Engine combustion chamber simulation

- Dynamic flow through moving valve

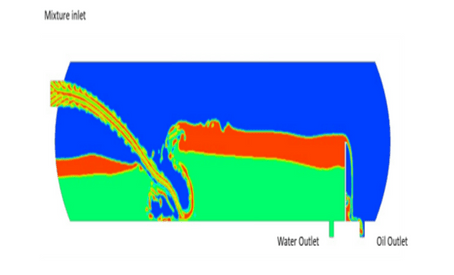

Multiphase Flow Simulation

Key Features

- Evaporators and condensers

- Chemical reactors

- Pneumatic conveyers

INDUSTRIES

We Transformed

Reactors

Productivity Improvement

Enhance reactor efficiency and performance with advanced CFD simulations

Solar Structure

Wind Load

Ensure solar structure stability with accurate wind load simulations using CFD

Radar Structure Cooling

Optimization of Cooling Fluid

Optimize radar structure cooling with CFD-driven fluid analysis

Bubble Column

Optimization and Design Improvements

Enhance bubble column performance with CFD-driven optimization and design improvements

Centrifugal Pump

CFX Project – First Time

Maximize centrifugal pump efficiency with comprehensive CFD analysis using CFX

Nuclear Reactor

Cooling

Optimize nuclear reactor cooling systems with advanced CFD simulations

Head/Tail Lamps

Thermal and Condensation

Ensure optimal thermal performance and reduce condensation in head and tail lamps with CFD analysis

Water management

Swirling and Cavitation Study of Sum

Improve water management by studying swirling and cavitation in sumps with CFD

Stirred tanks

Mixing simulation

Achieve 25% higher mass transfer in multiphase stirred tanks with our advanced flow simulation solutions to pharma company

Motor Temperature

Data from MotorCAD to Fluent

Integrate MotorCAD temperature data into Fluent for comprehensive motor cooling analysis