Overview

With ever shrinking timelines and budgets, CAE simulation is an important tool in the hands of designers and engineers. Modern CAE simulation tools help engineers run various what-if scenarios before a product is made. Our expert team of simulation engineers; can help you put together a simulation model which can accurately represent various phenomena experienced by the product. We have experience of putting together parametric simulation models with specific design goal. We work hand in hand with our customer teams to ensure that our simulation models meet strict deadline, meet quality criteria and reduce the overall development costs.

Fields / Applications

Our team of expert engineers has experience in using structural mechanic simulations across automotive, aerospace, process, and energy industries.

Emerging Technologies

Our team has experience in FSI, thermo-mechanical, EM-Structural coupled simulations. We have specialty skills in DEM-CFD coupled simulations. These simulations can be accomplished using either one way or two-way coupled methodology depending on the exact nature of the physics.

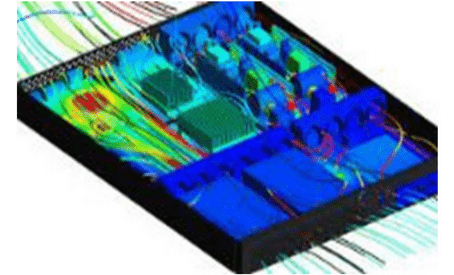

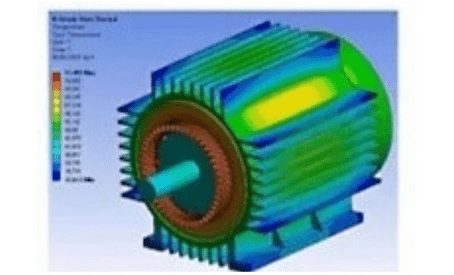

Multi-physics

Key Features

- Real world simulations require many physics interactions

- The interactions may be between structural, thermal, fluid, electromagnetics and other forces

- Real world multi-physics simulations will help to meet high quality targets

Simulation Driven Design

Key Features

- This is a process where CAE simulation is involved from the beginning of the product development

- Avoids multiple back and forth design verifications

- Drastically reduces the time taken for developing new products

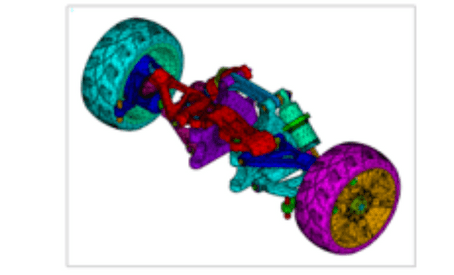

Multibody Dynamics

Key Features

- Kinematic and dynamic motion of Linkages

- Visualize motion and predict forces

- Vehicle dynamics

Light Weighting

Key Features

- Material saving leads to cost saving

- Greater energy efficient auto and aero applications

- EV – to compensate the added battery weight

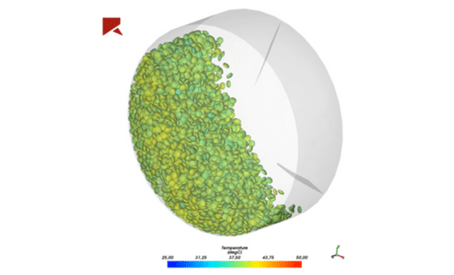

Particle Simulation-Discrete Element Method (DEM)

Key Features

- Real sized and real shaped particle movement simulation

- Realistic particle simulation for food, pharma and agricultural industries

- DEM – FEA integrated simulation

1D- Simulation

Key Features

- Performance prediction during concept development stage

- Complete system simulation

- Quick solutions even before making CAD models

Reduced Order Modelling

Key Features

- Simplifications of high-fidelity complex models

- Economic and quick solutions

- Helps to optimize the product design process

Digital Twin

Key Features

- Combination of machine learning analytics and physics based approach

- Realtime system analysis

- Useful for predictive maintenance

INDUSTRIES

We Transformed

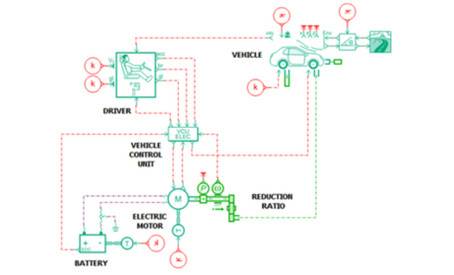

EV - Bus Performance

Integration of Vehicle, Motor and Battery

Optimize EV bus performance with integrated 1D simulation of vehicle, motor, and battery systems

EV 3Wheeler Performance

Integration of Vehicle, Motor and Battery

Optimize 3 Wheeler EV bus performance with integrated 1D simulation of vehicle, motor, and battery systems

Radome

First Time/EV Domain

Achieve low transmission loss in radomes with HFSS simulations

Radome

Low Transmission Loss

Achieve low transmission loss in radomes with HFSS simulations

Wireless Power Transfer

Wireless Power Transferr upto 1 KM

Enable wireless power transfer up to 1 KM with HFSS simulations

UV Ventilation Fan

Concept to Detailed Design

Transform UV ventilation fan concepts into detailed design engineering solutions

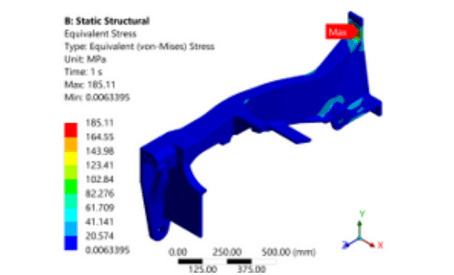

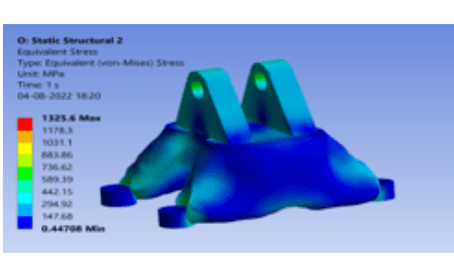

Gear Box Housing

Step by Step Optimization with FEA

Optimization and weight saving about 10 percent using simulation driven design approach

Composite Enclosure

300 M Underwater – Composite Layup – Sealing

Carbon-Composite lay-up design for an enclosure subjected to 300M underwater electronic enclosure

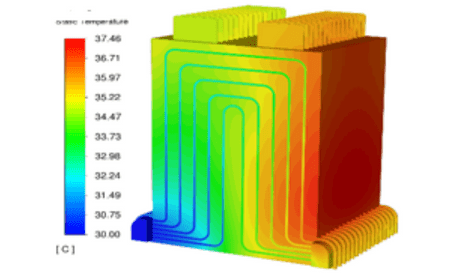

IR Cooker

Infra Red Heating – Concept to Detailed Design

Developed concept to detailed design for IR cookers with infrared heating solutions

Solar Structure

Optimization in Compliance with IS Standards

Simulation driven design and detailing of the panel support structures